As The EV Industry Grows, What Do Manufacturers Need in Their Inventory Playbook?

The electric vehicle industry is brimming with upward momentum. For starters, falling battery costs have caused electric vehicle purchases to increase by 43% from only a year ago; another study predicts that 57% of all global passenger vehicle sales will be electric by 2040.

With electric sales on the rise, competing energy sources are headed the other way. By 2030, the expectation is there will be a ban on the production of new petrol and diesel-powered passenger vehicles.

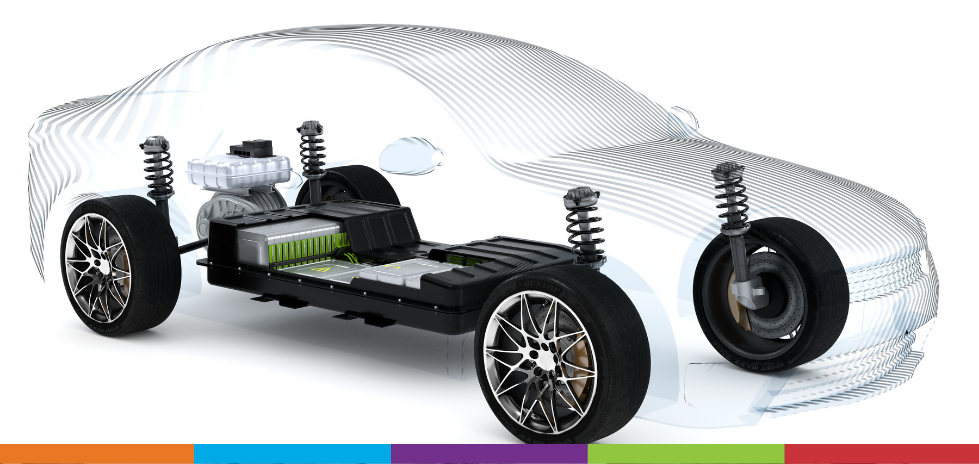

This uptick in demand means that development processes and electric vehicle supply chains will need to be streamlined and possibly reimagined. Electric vehicle fasteners, for instance, account for up to 50% of industry manufacturing SKUs and are essential to the vehicle’s infrastructure and its maintenance equipment. How can EV startups improve inventory management and build an array of lightweight, insulated, and cost-effective fasteners that keep up with industry demands? By taking these steps:

Get in Early With an Experienced Partner

Team up with a specialist that offers a complete end-to-end experience. This partner can handle design and engineering, BOM analysis, part consolidation, and identifying cost-saving opportunities that help you scale quickly and reduce waste.

Choose a partner that can match your needs for availability, complexity, and logistics. Furthermore, make sure that partner is focused and detail-orientated to stay aligned with the production timeline without requiring too many stops along the way.

Understand Your Development Cycle

The most common and disruptive fastening inventory management issues occur when supply chains go through their fastener supply too quickly. If it takes up to 20 weeks for a single fastener to move through the development cycle, any changes in availability can set projects back.

Cut down on lead times by understanding your development cycle. Plan for it, making sure your partner has experience handling the unique types of fasteners you may need.

Consider Additive Technologies to Increase Testability

It might make more sense for your project to develop through a series of tests and iterations. Build a prototype, test it, and create more cost-effective ways of producing it at scale.

Additive practices like 3D printing can help this method work, reducing your time to market. Experiment with virtual prototypes to see which ones might stick. Then, turn the specifications from those models into finished products that keep your vehicle both lightweight and functional.

These are just a few inventory management strategies that you can make your own. Want more information? Download our infographic “How Electric Vehicle Inventory Mismanagement Can Impact Success” to learn more.