What is Total Cost of Ownership and Why is it Important?

We’ve all heard the expression, “if something’s too cheap, it probably is” – often for good reason. A product or part may seem low-cost at first glance but have the costs beyond the purchase price been analysed?

It’s no surprise the primary focus for many companies is short term savings, but the best value is derived by looking at the entire life cycle. Total cost of ownership (TCO), sometimes referred to as, total lifetime costs, prompts businesses to assess all costs over the complete lifecycle — understanding what challenges and risks may arise, even predicting unknown variables.

The Iceberg

A quick Google search for TCO and you’ll find one key similarity between the many blogs and whitepapers on the topic — an iceberg analogy. Short-term costs, or purchase price illustrated by the tip of the iceberg, floating above sea level, clearly visible. The greatest mass of the iceberg, submerged, underwater masking the longer-term expenses — sometimes referred to as hidden costs.

So, what exactly are these costs, and why is it so important for businesses to look at the life cycle to establish total cost of ownership?

5 Steps to Understand Total Cost of Ownership

If we use product development as an example. Far beyond the cost of an individual component or part, we need to consider costs involved across the whole supply chain, administration, sourcing, transport, quality, performance…

There are 5 very distinct steps to examine that give us a better understanding of these hidden costs.

- Pre-Acquisition – though arguably the most important step, can result in extensive outgoings. This step can include research and sourcing, negotiations, visits, line walks and testing.

- Acquisition – you’ve selected your part and are happy with the quote, but what about delivery (logistics and transportation), installation, training and even spares?

- Operating – materials and energy usage, supplementary products and services required for parts to be used in the real world, on a busy 24/7 production line

- Maintenance – be it planned, preventative maintenance or a breakdown or repair, both are a cost to your business through downtime and ultimately lost production time

- End of Lifecycle – you’ve refined your designs or launched that new variant, and parts are no longer needed. Is decommissioning required? Disassembly or reconfiguration of supporting production equipment and tooling? Or perhaps disposal costs if stock holding has been miscalculated.

Now look at that list again and add operating expenditure (OpEx) or indirect costs including, but not limited to:

- General administration

- Labour

- Vendor management

- Finance

- Quality

- Engineering

- Inventory management

And let’s not forget, this can be per part….

This is of course a very high-level overview of costs that may be involved during the whole lifecycle, yet perfectly illustrates total cost of ownership – and how costs can quickly escalate if not carefully considered and planned.

How to Reduce Your Total Cost of Ownership?

Some of the steps outlined above are clearly more applicable to fully built and assembled products, such as machinery. Think of a CNC machine sat on busy shop floor. Through general use, this machinery or tooling is subject to constant wear and tear but is also prone to damaged from air borne contaminants and dirt ingress. In this instance, maintenance costs would need significant consideration.

So how does this methodology, this way of thinking come into play with much smaller, but no less essential parts? The very parts we rely on to hold this machinery together. TCO isn’t such an obvious proposition.

When we think of parts and components such as fasteners (bolts, nuts, rivets etc.) it’s useful to understand the importance of a VMI or, Vendor Managed Inventory. Previously we wrote about how VMI programs lower your total cost of ownership. In short, by using a VMI, the vendor holding your stock (or MOQ) assumes all the cost and associated risk. If we explore this concept in more detail if becomes clear why.

VMI plays a key role in the reduction of costs to the end-user by:

- Helping to control operating costs including labelling, packaging, and the storage of thousands of parts. It’s estimated that an average car is built using over 3500 fasteners, an airplane, 1 million plus. Granted, these are extreme examples – but you can imagine how much space these fasteners would consume in a production line environment. A VMI helps manufacturers reclaim physical space and has a positive effect on cash flow by reducing stock holding requirements.

- Reduces the number of staff needed to perform inventory management tasks. Managing countless purchase orders, handling the product upon delivery, the goods-in process — locating the parts in the correct area and ensuring they’re placed in correctly labelled bins. These are all time (and costly) processes that also expose your production line to risk if mis-managed.

- Lower acquisition costs result in significant upfront savings to customer capital. By using a strong supply chain, buying in higher volumes, consolidating parts to control freight charges, you’re guarding against price increases and unexpected import duties/tariffs. Not only that, a VMI allows you to use the vendor as a buffer to avoid potential supply issues, securing stock for the long-term. How many businesses would plan in the macro with hindsight of Covid-19?

Consolidate and Save

It’s not just VMIs themselves we need to consider, let’s take a step back and look at the products that these very VMI programs are based upon.

Once more, if we take direct materials — fasteners, and C-Class components as an example – high volume items that could prove difficult to manage. We must think about other products that fit this same criteria.

PPE such as face masks, gloves and workwear, and industrial supplies, including abrasives, adhesives, and consumables. Important items that staff simply can not do perform their duties without? Do businesses really see the best ROI by tying up skilled team members in the management of these parts?

Sourcing from fewer suppliers means less invoices, and subsequently, less time spent by staff cross checking incoming stock. General vendor consolidation could find manufacturers saving incredible amounts of time, cost and effort.

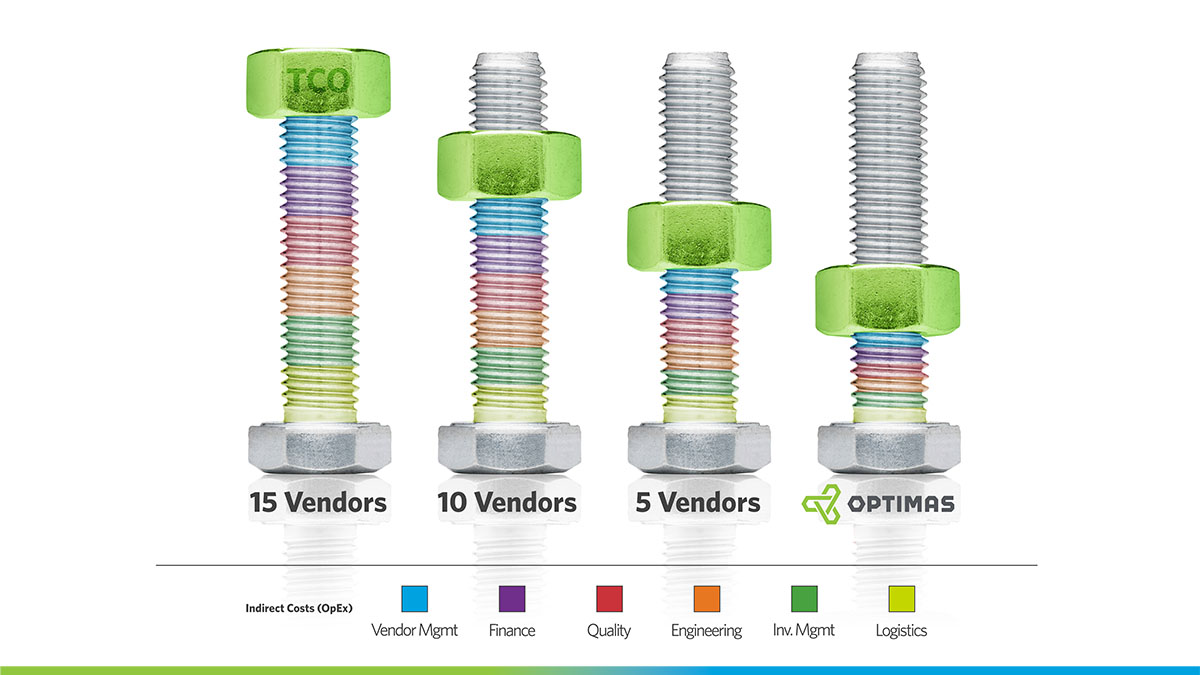

With over 5,000 loyal customers worldwide, Optimas understands customer’s requirements and can rapidly adapt to meet their needs. That all starts with finding innovative ways of reducing costs. Although not an iceberg, our bolt graphic illustrates how, through partnering with Optimas and reducing vendors, the hidden costs become less and less overtime.